Our Sand Casting Foundry is equipped with Superior Equipment for high production rates and repeatability. We produce moulds and cores in Alpha set no bake process and it is Environment friendly. The benefits of the Alpha-set System are most noticeable in steel castings resulting in a significant improvement in casting quality and reduced cleaning room costs.

- Our Total Installed capacity of Sand Casting Steel Foundry is 2000 MT/Annum

- Manual moulding for large Castings : Maximum moulding box size : 3300mm x 3000mm

- Semi Mechanised moulding line for medium size castings : 1200 x 1200mm

- Weight Range for Castings : 15 – 6000 Kgs.

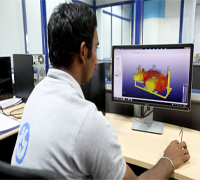

Engineering & Pattern shop

- We use Z-Cast simulation software to predict and prevent challanges before a single mould is poured.

- Possible problem areas and defects that might occur during the casting process can be seen as visual outputs with the help of this Simulation software.

- By using the simulation software we can analyze the solidification, flow and heat stress module.

- We store our Customer patterns in a separate warehouse from the daily operation of the foundry. If necessary, we can produce patterns according to your blueprints.

Moulding line

Our foundry has the capacity to manufacture castings through the alphaset no-bake and processes. We produce sand moulds using the semi-mechanized no-bake moulding system, giving us great flexibility as well as the ability to pour castings up to few thousand kilograms.

In order to improve the productivity and eliminate the need for heat or gassing we are using no bake process. The no bake process helps us to free from veins, scabs, erosions & hot tears due to excellent high temperature properties superior to other core making process.

- Our Semi-machanized No-bake moulding system, presents the opportunity for great flexibility in mould making.

- It is possible for us to accommodate different moulding sands, different flask heights and different metals all within a single line.

- Our semi mechanized moulding lines are installed with resin bonded sand system and complete reclamation facility.

Melting Units

All melting units are accomplished using coreless induction furnaces with the following units.

- 175 kW – 100, 250 & 500 kg crucibles – each 1 number

- 350 kW – 250 & 500 kg crucibles – each 1 number

- 1500 kW – 1500, 3000 & 6000 kg crucibles - each 1 number

Heat Treatment Facilities

We have a combination of electric and oil fired heat treatment furnaces, which are

- 250 kg & 1000 kg electric furnace – each 1 number

- 4000 kg oil fired furnace – 2 numbers

- Water quenching facility up to 80,000 litres capacity with forced air cool facility.

- All our heat treatment furnaces are calibrated by TUV & Lloyds according to API 6A, ASTM A991 & NORSOK M-650 standards.

Fettling Facilities

We have a fully equipped fettling and welding unit to ensure the shorter lead time and reliable quality.

Cast parts are shaken out of the moulding sand, which is recycled